Using and maintaining your equipment

Once you've selected an approved type of weighing or measuring equipment, you must use it correctly and ensure it remains accurate.

Using your weighing or measuring equipment

Weighing, measuring or counting goods in front of the purchaser

If you weigh, measure or count goods in front of the purchaser, your equipment must be situated so that both of you can easily see:

- the weighing or measuring of the goods, and

- the recorded or indicated weight or measure.

Prerequisites for using weighing equipment

Before using weighing equipment, there are a number of actions you can take to help ensure it is being used appropriately.

Zero function

Prior to weighing goods, make sure the indicator is reading zero (0) before you use the instrument.

Tare function

If you're selling pre-packed goods, or loose goods that you're packaging in front of the purchaser (such as deli bags or pottles), you must deduct the weight of all packaging material. If your weighing equipment has a tare button, you can use this to deduct the weight of the packaging or container before you weigh the goods (that is, tare off the packing material).

Levelling

Weighing equipment can be inaccurate if they're not level. Regularly check the level indicator on, if there is one. If equipment is moved, recheck the level indicator to ensure the equipment is level before use.

Setting the control point on checkweighers

When using automatic weighing or measuring equipment, checkweighers can be used. These can be introduced at the end of the production line to ‘reject’ anything below the stated net quantity of the product that is being packed. Manufacturers and packers who knowingly set their checkweigher to accept products that are below their stated quantity may leave themselves open to enforcement action for packing short measure goods.

Ensuring your equipment is accurate

To ensure your weighing or measuring equipment is accurate and meets the requirements of the legislation:

- have it verified by an Accredited Person

- request an annual certificate of accuracy, and

- periodically do your own accuracy checks and record the results.

Verification

You must have your equipment verified and stamped with a Mark of Verification by an Accredited Person before it can be used for trade. An Accredited Person is a company or individual who Trading Standards has approved to verify the accuracy of weighing and measuring equipment.

If the Mark of Verification has fallen off, been damaged or been removed for any reason, you must have your equipment re-verified by an Accredited Person immediately, as it's an offence to have unverified equipment in use for trade.

For more information see:

What equipment your business can use

Visits from Accredited Persons

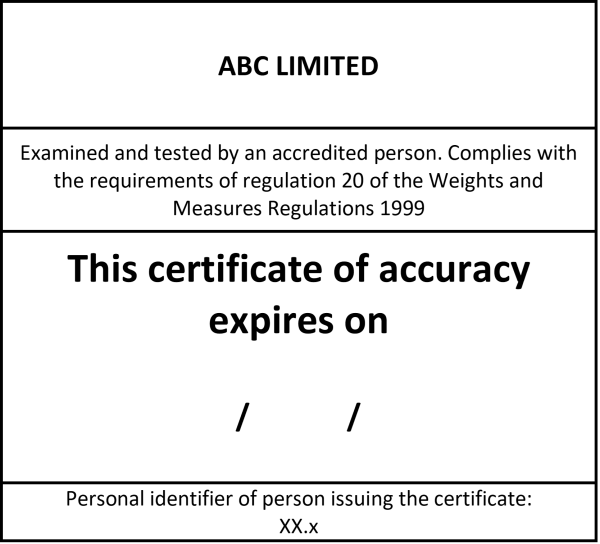

Certificate of accuracy

An Accredited Person can issue you with a certificate of accuracy if you ask. This is valid for 12 months from the date of the test and assures consumers that your weighing or measuring equipment has been independently tested.

Example Certificate of Accuracy

Example Certificate of Accuracy image description

This is an example of a Certificate of Accuracy label. This example shows that the accredited person is ABC Limited. It contains text indicating that they have been examined and tested by an Accredited Person, and that they comply with the requirements of regulation 20 of the Weights and Measures Regulations 1999. The label also shows that the certificate has an expiry date, and contains the personal identifier of the person issuing the certificate.

Maintaining a current certificate of accuracy for your equipment is voluntary, however having one may provide you with a defence if your equipment is found to be inaccurate (this is termed 'false or unjust' in the legislation).

Note that this defence can only be used if:

- the equipment's certificate of accuracy is current, and

- the operator or owner of the equipment didn't know or have any reason to suspect or believe the equipment was inaccurate.

Please see our Certificate of Accuracy page for more information.

Do your own checks

There are some simple things you can do to ensure your weighing equipment is accurate between annual certification checks. These include:

- ensuring weighing equipment is level and indicates zero before use

- daily or weekly accuracy checks using a calibrated test weight and recording the results

- regular checks of the net weight or measure of packaged goods, paying particular attention to goods packed ‘in-house’, and

- removing any incorrectly weighed goods from sale or distribution and isolating them from other stock.

Your system for checking weighing or measuring equipment and products should be documented and monitored by management.